-40%

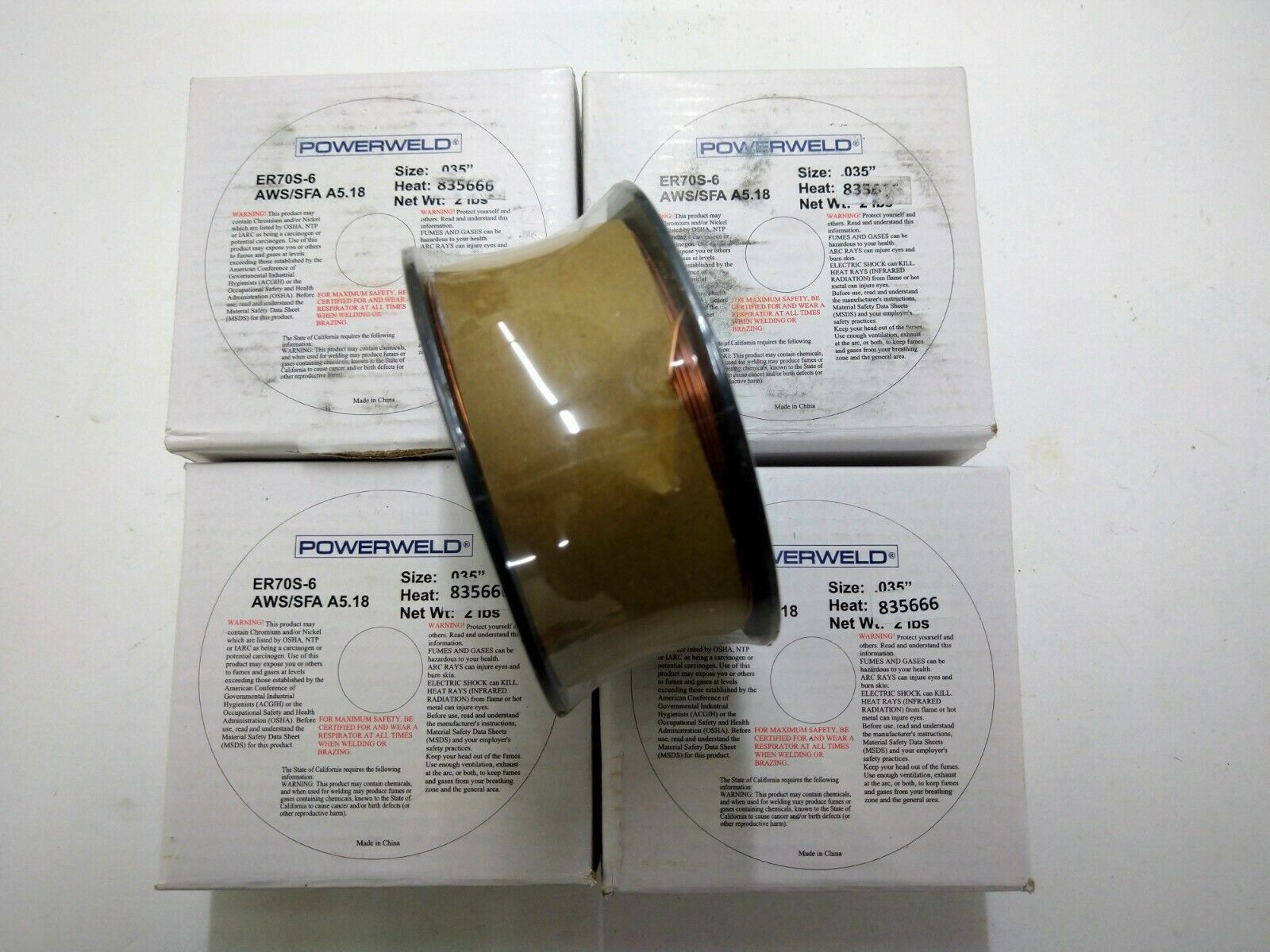

(4) ER70S-6 Mild Steel Mig Welding Wire 4 x 2lb Each .035 Diameter 0.9mm

$ 15.57

- Description

- Size Guide

Description

MIG Welding WireER70S-6 Mild Steel 2lb Each .035 Diameter

2Lb x 4 Rolls

8 Lb Total

Fast shipping USPS

Class:

ER70S-6

AWS:

A5.18

Conforms to Certification: AWS A5.18 ASME SFA A5.18

Weld Process Used for Mig (GMAW)

AWS Chemical Composition Requirements

C = 0.06 – 0.15

Ni = 0.15 max

Mn = 1.40 – 1.85

Cr = 0.15 max

Si = 0.80 – 1.15

Mo = 0.15 max

P = 0.025 max

V = 0.03 max

S = 0.035 max

Cu = 0.50 max

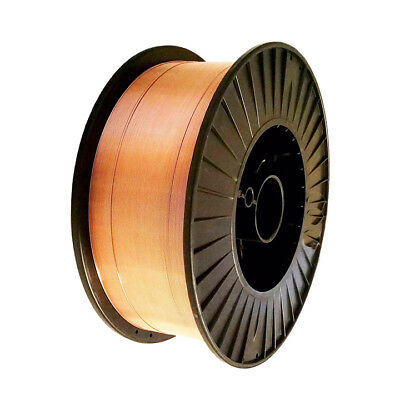

Available Sizes

.023 x 2#, 11#, 33#

.030 x 2#, 11#, 33#

.035 x 2#, 10#, 33#, 44# also in DRUMS

.045 x 2#, 10#, 33#, 44# also in DRUMS

.052 x 33# also in DRUMS

1/16 x 33# also in 60# coils

Application

Type ER70S-6 is a wire with higher levels of Deoxidizers welding of steels with moderate amounts of scale or rust. (Mn & Si) compared to other carbon steel wires. This wire is suitable for welding of steels with moderate amounts of scale or rust.

For Mig welding use Carbon Dioxide or Argon + Co2 or Argon + 2% Oxygen as shielding gases.

Deposited Chemical Composition % (Typical)

C = 0.09

P = 0.012

Si = 0.95

Mn = 1.65

S = 0.018

Cu = 0.35

Deposited All Weld Metal Properties % (As Welded)

Tensile Strength

78,000 psi

Yield Strength

65,500 psi

Elongation

24%

Deposited Charpy-V-Notch Impact Properties %

45 ft. lbs. (at -20ºF)

Recommended Welding Parameters (GMAW “Mig Process”)

Wire Diameter

Volts

Amps

IPM

Short Arc Welding

.030

16 – 18

75 – 125

176 – 324

.035

15 – 18

100 – 160

132 – 228

.045

17 – 18

100 – 120

149 – 208

Spray Arc Welding

.030

26 – 28

200

560

.035

27 – 29

250

504

.045

28 – 31

265

336

.052

29 – 31

300 – 340

280 – 350

1/16

30 – 36

350 – 400

220 – 280