-40%

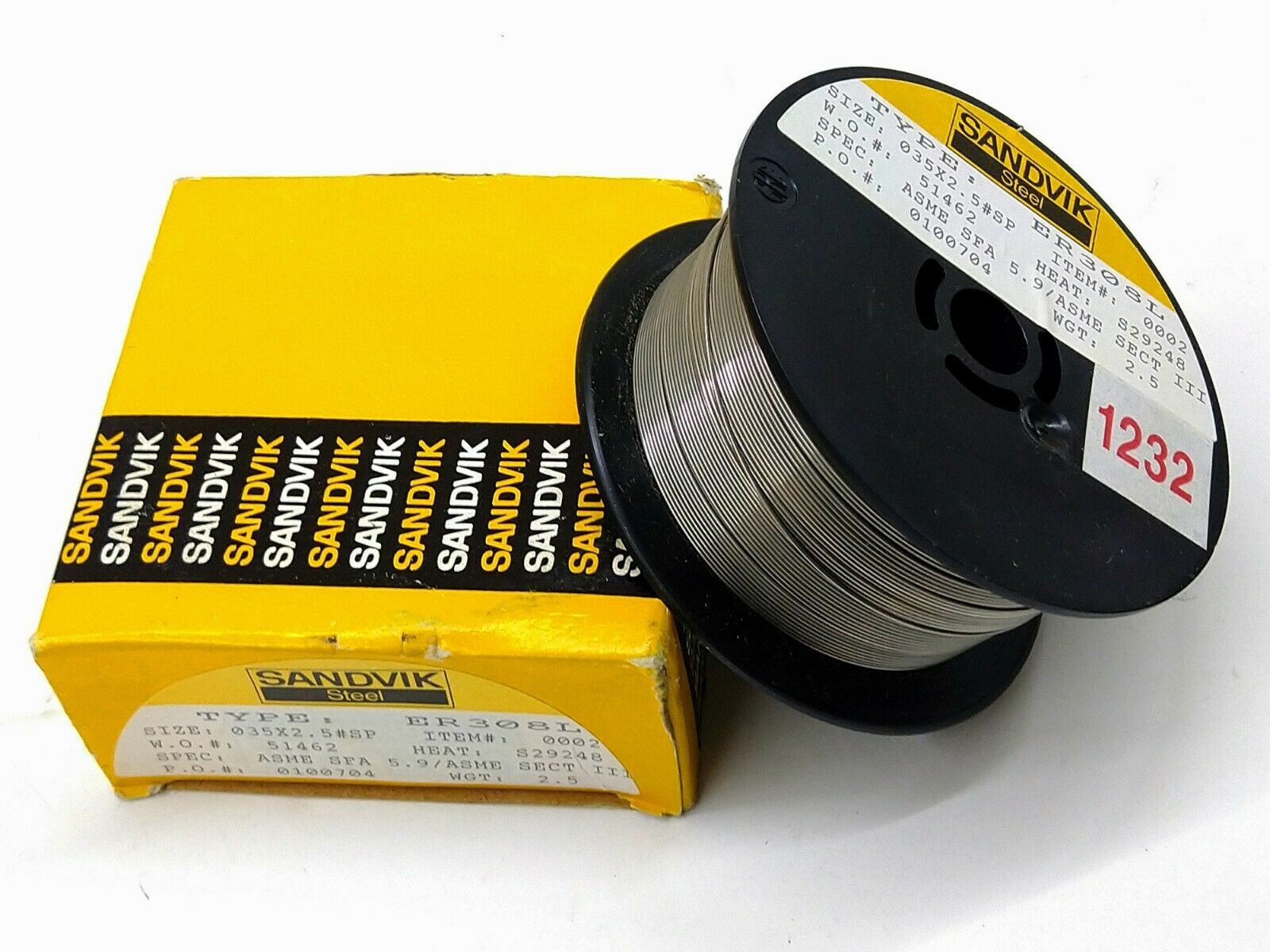

MIG Welding Wire ER308L Stainless Steel .035" 2.5Lb x 2 (2rolls)

$ 18.47

- Description

- Size Guide

Description

SANDVIK MIG Welding Wire ER308L Stainless Steel .035"2.5Lb x 2 Rolls

5 Lb Total

Fast shipping USPS

Class:

ER308L

AWS:

A5.9

Conforms to Certification: AWS A5.9 ASME SFA A5.9

Weld Process Used for Mig (GMAW) and Submerged Arc (SAW)

AWS Chemical Composition

C = 0.03 max

Cr = 19.5-22.0

Ni = 9.0 – 11.0

Mo = 0.75 max

Mn = 1.0 – 2.5

Si = 0.30 – 0.65

P = 0.03 max

S = 0.03 max

Cu = 0.75 max

Available Sizes

Diameter X Spool Sizes

Diameter X Coil Sizes

.025 x 2#, 10#, 25#

1/16 x 60# & mill coil

.030 x 2#, 10#, 25#, 30#, 33#

5/64 x 60# & mill coil

.035 x 2#, 10#, 25#, 30#, 33#

3/32 x 60# & mill coil

.045 x 2#, 10#, 25#, 30#, 33#

1/8 x 60# & mill coil

1/16 x 10#, 25#, 30#, 33#

3/16 x 60# & mill coil

5/32 x 60# & mill coil

Application

ER308L has the same analysis as type 308 except the carbon content has been held to a maximum of .03% to reduce the possibility of intergranular carbide precipitation. ER308L is ideal for welding Types 304L, 321, and 347 stainless steels. This is a suitable wire for applications at cryogenic temperatures.

Deposited Chemical Composition % (Typical)

C = 0.02

Si = 0.32

Mn = 1.70

P = 0.011

S = 0.009

Cr = 20.0

Ni = 10

Mechanical Properties (R.T.)

Yield Strength

57,000 psi

Tensile Strength

87,000 psi

Elongation

34%

Reduction of Area

56%

Deposited All Weld Metal Properties

Data is typical for ER308L weld metal deposited by Mig using Argon + 2% oxygen as the shielding gas. Data on sub-arc is not presented, as sub-arc is dependent on the type of flux used.

Recommended Welding Parameters

GMAW “Mig Process”

Reversed Polarity

Wire Diameter

Wire Feed

Amps

Volts

Shielding Gas

Gas CFH

Short Arc Welding

.030

13-26

40-120

16-20

Argon+2% O2

25

.035

13-26

60-140

16-22

Argon+2% O2

25

Spray Arc Welding

.035

20-39

140-220

24-29

Argon+2% O2

38

.045

16-30

160-260

25-30

Argon+2% O2

38

1/16

10-16

230-350

27-31

Argon+2% O2

38

Other shielding Gases may be used for Mig welding. Shielding gases are chosen taking Quality, Cost, and Operability into consideration

Recommended Welding Parameters

SAW “Submerged Arc Welding Process”

Reversed Polarity Suggested

Wire Diameter

Amps

Volts

3/32

250-450

28-32

1/8

300-500

29-34

5/32

400-600

30-35

3/16

500-700

30-35

Both Agglomerated and fused fluxes can be used for submerged arc welding.

Note: The chemical composition of the flux mainly affects the chemistry of the weld metal and consequently its corrosion resistance and Mechanical properties.