-40%

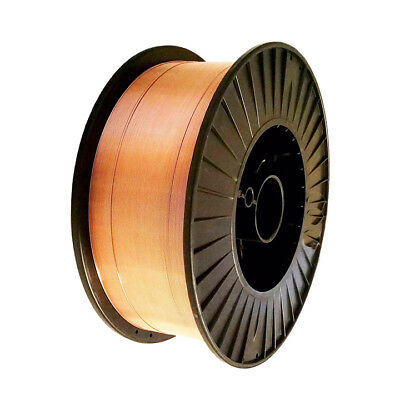

Rockmount Nassau Olmpia B flux core size 045 25lbs Welding wire

$ 158.39

- Description

- Size Guide

Description

OLYMPIA B FLUX COREFLUX CORE ARC WELDING FCAW-WIRE

FEATURES

Excellent Severe Abrasion Resistance • High Hardness: 62 - 65 RC • Unsurpassed Self-Shielded Running Characteristics • Mild Impact Resistance • Exceptionally High Alloy Content • High Heat Hardness To 1200ºF (664ºC)

For hardfacing, to resist abrasion on carbon steels, alloy steels, cast iron and manganese. • Excellent Severe Abrasion Resistance • High Hardness: 62 - 65 RC • Unsurpassed Self-Shielded Running Characteristics • Mild Impact Resistance • Exceptionally High Alloy Content • High Heat Hardness To 1200ºF (664ºC) Olympia B Flux Core is a self-shielded hardface wire with an exceptionally high alloy content for resistance to extreme abrasion applications. The deposits also resist mild impact and high heat. Very suitable for vertical down-hand welding (.045 recommended). Olympia B Flux Core has a special metal core composition which provides superior abrasion resistant alloying that includes chromium, molybdenum, boron and vanadium. A total alloy content that exceeds 15%, provides an excellent high hardness deposit. This is combined with excellent running characteristics and slag free deposits. Olympia B Flux Core deposits will stress crack due to their high hardness. Deposits should be limited to two passes. • Not required. • Argon/CO2 or 100% CO2 will enhance running characteristics. • Self-Shielded. • An Argon/CO2 or 100% CO2 gas shield will enhance running characteristics. • A 98/2 Argon/CO2 mix will allow spray arc transfers. • Will run vertical down. • We recommend Gemini Anti-Spatter spray for lasting protection of your contact tip and MIG nozzle (see chemical aids in Abrasives & Metal Working products section). •