-40%

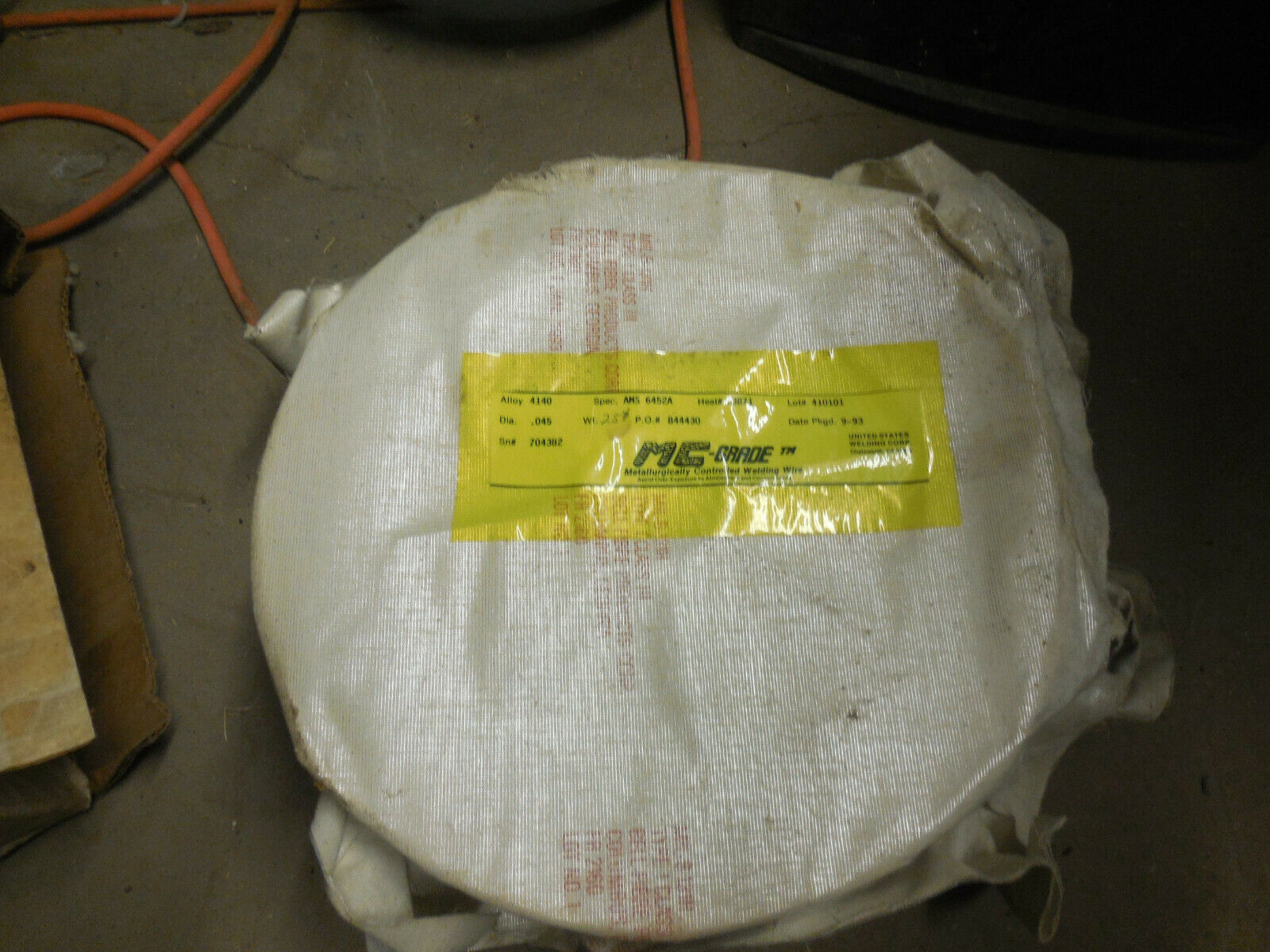

united states welding corporation WT 4140 VM – AMS 6452 – Low Alloy Steel Weldin

$ 63.88

- Description

- Size Guide

Description

united states welding corporation WT 4140 VM – AMS 6452 – Low Alloy Steel Welding Wire 25 pounds.AMS 6452

UNS G41400

AISI 4140

USWC 6452 (V)

TURBALOY® 4140 is produced by vacuum induction melting and remelting technques. The

final wire is manufactured by special lubricant-free, roller-die forming followed by surface abrasion

and cleaning processes.

These manufacturing processes ensure consistent metallurgical integrity of the alloy with regard to control

of trace elements and physical purity of the welding wire surface.

TURBALOY® 4140 is a high strength Cr,Mo C steel filler metal used for fabricating critical joints

of similar composition base metal.

AMS 6395, 6349, 6529, 6382, 6381, 6390.

UNS G41400 - AISI 4140.

Tubular frames for engines.

Weapons and defense equipment.

Tooling.

Use ultra clean weldment preparation. Refer to PH & PWHT chart.

Carbon

Manganese

Silicon

Sulfur

Phosphorus

Chromium

Melting Point: 2740°F

CVN: 58.3ft lbs at 0°F, 100% shear.

(Minimum specification requirement: 28 CVN).

DFARS Compliant www.usweldingcorp.com

AS 9100

6452

MIL-R-5632 Type II

(AMS 6382 Reference)

0.95Cr 0.2Mo (0.38-0.43C)

Nickel

Molybdenum

Copper

Oxygen

Nitrogen

Hydrogen

Iron

STRAIGHT LENGTHS SPOOLED WIRE

5 lb. (2.2kg) packs

36” (914mm) lengths

Flag tagged for traceability.

(Double tagging and other lengths on request)

Wide range of diameters.

Precision layer wound, with controlled cast and helix

12” (300mm) diameter spools standard

8” (200mm), 4” (100mm) and proprietary spool sizes

on request.

Wide range of diameters and spool weights.

Sealed, air-evacuated, argon purged Vapor Barrier e nvelopes with desiccants ensure full protection from

atmospheric contamination and prolonged shelf-life.

0.38

0.75

0.15

-

-

0.80

0.43

1.00

0.35

0.008

0.008

1.10

0.25

0.25

0. 35

0.0025 (25ppm)

0.0050 (50ppm)

0.0010 (10ppm