-40%

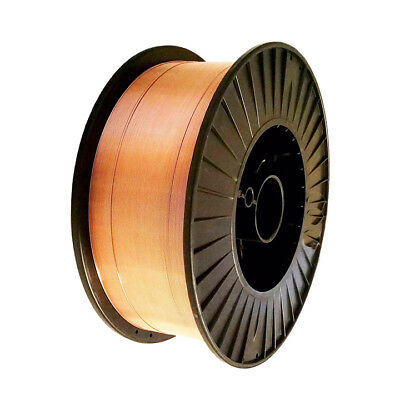

Welding Wire 100 Rolls Tri-Mark Hobart Flux Core High Strength Lo Alloy .052"

$ 2376

- Description

- Size Guide

Description

You are buying100 Rolls

33 pounds per roll

Unbelievable DEAL!

3300 POUNDS

Tri-Mark Wire

.052" (1.4mm)

33lbs spool (15kg)

Item Number: S283815T -- K29

Material: Steel --

2% nickel

~Check out our additional equipment and supplies!~

GAS SHIELDED FLUX CORED WIRE

TM - 811N3 offers excellent arc stability and low spatter using CO2.

These weldability features, combined with low diffusible hydrogen levels and good impact values, make the TM - 811N3 a superior choice for shipbuilding, offshore drilling rigs, HSLA steels, and weathering steels where color match is not required.

The wire is recommended for single and multiple pass welding in all positions using CO2.

Product Characteristics:

• Superior welding characteristics in all positions.

• 2% nickel weld metal promotes good CVN* impact properties.

*Charpy V-Notch test or toughness test.

• Can be used with 100% CO2

• Capable of being used to weld several HSLA* steels.

*(

HSLA steels are also more resistant to rust than most carbon steels because of their lack of pearlite – the fine layers of ferrite (almost pure iron) and cementite in pearlite [citation needed] HSLA steels usually have densities of around 7800 kg/m3).

Specifications: (This is military surplus)

•

Mil E 24403/2 (made for the military specs.)

•

Class Mil 101 TC

•

Class Mil 101 TM

Shielding Gas:

100% CO2

50 cfh

Welding Positions:

All positions

Diameters:

.052”

Weld Test Parameters:

TM-811N3 .052” diameter electrode was welded using 100% CO2shielding gas with flow rate of 40 cfh, 200 amps (251 IPM), DCEP, and 25 volts with 3/4” electrical stickout and 250 deg ± 25 deg F interpass temperature.

A total of five layers were welded, two passes each for Layers 2 through 5, one pass on Layer 1.

The direction of travel was reversed for each layer.

Typical Undiluted Weld Metal Chemistry:

C

Mn

Si

P

S

Ni

100% CO2

0.04

0.98

0.33

0.016

0.012

2.00

Typical Mechanical Properties:

100% CO2

Tensile Strength

97,900 psi (675 MPa)

Yield Strength

89,700 psi (619 MPa)

Elongation

22.5%

CVN @ 60 deg F (51C)

60 ft•lbs (81 J)

The above properties were determined with 100% CO2 shielding gas.

Recommended Operating Parameters:

The information below was determined by welding performed with 100% CO2 shielding gas at a flow rate of 35 cfh.

Diameter,

Arc

Current

Approx.

Deposition

Electrical Stickout

Voltage

DCEP (+)

Wire Feed Speed

Rate

(ES) Position

(volts)

(amps

(in/min

(lbs/hr

.052”

22

100

95

2.4

1/2” to 3/4”

29

300

420

to

Flat and Horizontal

31

350

520

15.3

-

--

-----

--

24

100

95

2.4

25

200

240

Bold

— Optimum parameters for welder appeal.

Notice:

Actual use of the product may produce varying results due to conditions and welding techniques over which Tri-Mark has no control, including, but not limited to, plate chemistry, weldment design, fabrication methods, electrode size, welding procedure, service requirements, and environment.

The purchaser is solely

responsible for determining the suitability of Tri-

Mark products for the purchaser’s own use.

Any prior representations shall not be binding.

Tri-Mark disclaims any warranty of merchantability or fitness for any particular purpose with respect to its products.

Caution:

Consumers should be thoroughly familiar with the safety precautions shown on the Warning Label posted on each shipment and in

American National Standard Z49.1, “Safety in Welding and Cutting,” published by the American Welding Society, 550 NW LeJeune Road, Miami, FL 33126, and OSHA Safety and Health Standards 29 CFR 1910, available from the U.S. Department of Labor, Washington, D.C. 20210